State-of-the-art interior illumination systems – theory and practice

In the field of illumination systems, such factors as electric parameters and energy efficiency are no longer the only key characteristics taken into account. Manufacturers increasingly emphasise also more comprehensive and subtler advantages of their products. Let us check, then, what the suppliers' efforts are aimed at and how new technologies can contribute to improving the comfort of our everyday life.

Once the LED technology dominated the illumination system market, it did not just stop evolving. And even though semiconductor designs are employed in almost every typical illumination-related application, manufacturers constantly outdo themselves, striving to improve their products even further. Moreover, having advanced enormously in terms of product performance, engineers now concentrate on other aspects of their solutions, such as: user comfort, mimicking natural light, adjustable colour warmth, and other component parameters. Bridgelux is famous for innovations in this field, and its product assortment provides a perfect illustration of the current trends on the global markets. This article is devoted to the functions and applications of LED illumination systems, and also discusses how cutting-edge products provided by the leading suppliers are designed to meet the needs resulting from the application of the most demanding solutions.

This article covers the following issues:

What light is perceived as “natural light”?

What is the Colour Rendering Index?

What is understood as the “colour temperature” of light?

Advantages and limitations of LED-based light sources

Why is the quality of LEDs represented not only by their parameters?

Thrive™ technology and efficient illumination similar to natural light sources

Human Centric Lighting

LED light sources similar to classic light bulbs

Energy efficient light sources for shopping centres

ARTIFICIAL LIGHT – THEORY AND PRACTICE

Firstly, let us analyse how people perceive colours, and discuss a few issues related to the field of optics and illumination. We will do our utmost to approach the topic in the most comprehensive way, while simultaneously making sure that what we say is fully practical.

Perception of colours by the human eye

Firstly, we must state the obvious: colour is nothing more than the electromagnetic radiation wavelength. If the radiation frequency is limited by the spectrum registered by the human eye, it is colloquially called “light” (visible light, in the scientific terms). These frequencies range from approximately 400 to 790 THz, i.e. their wavelengths are from 380 nm (red) to 750 nm (violet). What humans perceive as “white” light is a mix of different wavelengths, and our senses have adapted to perceiving sunlight as “natural” white. Therefore, when we speak of “natural light”, we take daylight as a reference point (although, in fact, solar radiation reaching the Earth is not perfectly homogeneous).

Theory, technology, practice

For biological reasons, daylight is the most comfortable kind of light for the human eye. It also provides optimum observation conditions. In other words, it is assumed that an artificially illuminated object appears to us “as it really is” only if sunlight-imitating lamps are used for illumination purposes. This phenomenon influences two major technological issues.

Firstly, the question of optimum interior illumination is really significant, especially for work and study spaces where we spend longer periods of time. In most countries, local regulations govern the properties of illumination systems installed in offices, production facilities, etc. in order to protect the personnel, visitors and customers from having to spend much time in conditions that could have detrimental impact on their (both physical and mental) health.

Some of the most important areas where the aim is to render “natural” colours as closely as possible to ensure objective observation results include: printing, textile industry, chemistry (dyehouses), as well as medicine (diagnostics, surgery) and other sciences. Illumination is also vital in such areas as photography, film-making and TV. Obviously, in these application fields, intentional manipulation of the light hue is quite common (pale blue lighting imitates night, orange lighting imitates fire, etc.), but nowadays all such effects are usually introduced in post-production, at the colour correction stage, by processing neutrally filmed material. It is similar in sales and marketing, i.e. if a supplier wants to photograph a product so that the customer can see the goods faithfully represented in a catalogue or on the screen, lamps emitting “natural” light should be used. The same applies to display/shop illumination.

Colour Rendering Index (CRI)

At this point, it should be quite obvious that the issue of the “naturalness” of light is not only important, but also very comprehensive and subjective, as the human brain tends to involuntarily correct its observations depending on illumination, and our sight is susceptible to optical illusions. The process of determining whether the radiation emitted by an incandescent bulb or another device used for illumination purposes is actually similar to the daylight, in terms of components and their intensity, requires conducting precise measurements over a wide spectrum of frequencies. In order to simplify it by reducing it to a single value, the CRI index is commonly used.

CRI stands for Colour Rendering Index. The CRI values range from 0 to 100, where the upper limit indicates the ideal imitation of averaged sun radiation (within its visible spectrum). In practice, this means that objects illuminated by such a light source appear the same to the human eye or camera sensors as they do under a clear sky on a sunny day. The optimum value is CRI ≥ 80 (household or public utility space illumination), whereas CRI exceeding 90 is required practically only in professional settings (medical applications, exhibitions, etc.).

TM-30 system

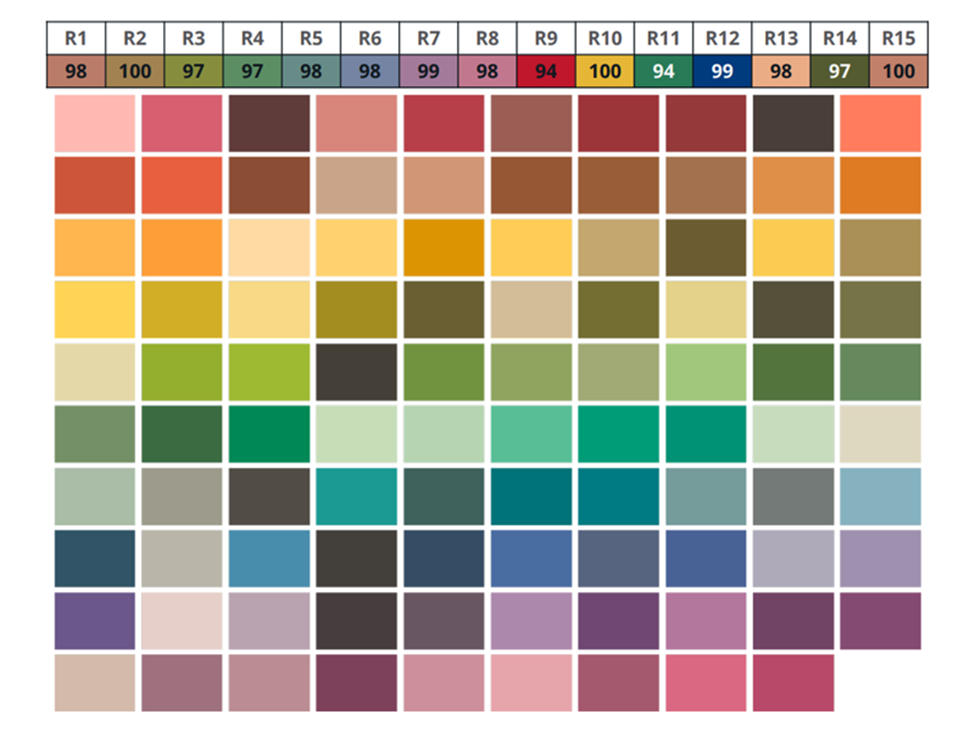

Note that there is no scientific definition of light “naturalness”, which results in a multitude of competing solutions developed to standardise this issue. CRI is one of such solutions, and it is quite well-established, as it has been applied since the 1960s and accepted as a standard all over the world. Nevertheless, CRI measurements are performed on only eight colour samples (from R1 to R8 – see below). This idea is pushed further by the broader and more restrictive TM-30 system recommended by the Illuminating Engineering Society, and adopted under this name by the American National Standards Institute (ANSI). The TM-30 methodology specifies 99 hues, derivatives of 15 colours (marked as R1 – R15). Measurements are taken for each hue in order to examine not only the colour rendering index, but also the colour saturation degree when illuminated by the source under test, so that the test results are more precise and can be related to specific application parameters.

Colours used in IES tests: 15 basic and 99 auxiliary (constituent) colours.

How does CRI relate to the light temperature?

Light colour temperature is not directly related to CRI, as it refers to the human perception of artificial light colours, but not to the accuracy with which this light renders the colours of the objects from which it is reflected (the indirect relationship between these scales is explained below). LED bulbs can be designed to (literally) give the impression of being a neutral light source, whereas its radiation is a mix of only a few, unbalanced frequencies. Under such light, certain colours appear more or less intense “than they really are”. This phenomenon can sometimes be encountered in the least expected circumstances, for example, with well-known figures such as politicians and celebrities complaining that their complexion looks unhealthy or unappealing under energy-saving floodlights. On the other hand, in museums, light that is “warmer” than neutral, but with a very high CRI (e.g. 95), is sometimes used, giving the visitors the illusion that they interact with the exhibits in relaxing morning or afternoon illumination conditions, while allowing the nuances of their colours to be observed.

CCT (Correlated Colour Temperature) is a scale comparing the human perception of light temperature to the radiation emitted by a surface of a perfect black body heated up to a certain temperature. This scale is more clearly represented by the analogy to a heated up metal or classic light bulb filament which, as the temperature increases, becomes red, and then orange (approx. 1500 K – candle flame), and then yellow (approx. 3000 K – rising sun), and, finally, white (4000–5000 K – neutral white). Further on, the scale classifies light (unintuitively) specified as cold, i.e. bluish, light (from 6000 K upwards), up to the sky colour (10000 K). These intermediate values are quite common, as they are specified by manufacturers on the packaging and enclosures of incandescent lamps, fluorescent lamps, LED strips and other illumination system components. CCT is a key value when performing tests to determine the colour rendering index, which are based on relative measurements (i.e. relative to sunlight). For example, when measuring the CRI value of a warm-light-emitting LED strip, an adequate time of day or an incandescent source with a comparable CCT value is taken as a reference.

Despite a warm hue, illumination with high CRI does not suppress the intensity of blue hues.

LEDs as the sources of white light

Employing semiconductors, specifically LEDs, as light sources comes both with advantages and disadvantages. The advantages of this technology are commonly known, and include the excellent energy efficiency (most energy is converted into electromagnetic radiation instead of heat, as is the case with incandescent sources), small component size, wide and varied range of solutions, extensive adjustment possibilities, etc. On the other hand, unfortunately, the LED technology is characterised by certain restrictive requirements. They are mainly related to relatively narrow brackets of power supply parameters, requiring the application of suitable (constant-voltage or constant-current) power supply modules, which in turn results in hindering scalability. Luckily, these problems are not encountered by consumers who mostly purchase standard LED bulbs that are factory-adapted to traditional threaded sockets, equipped with capacitor-based, transformerless converters. Installers, designers and manufacturers can be affected by certain technological limitations, though. These are mainly related to such details as the CRI factor, heat dissipation or cable selection aimed at neutralising DC voltage drops within longer power lines.

A few brief theoretical considerations

The “animated” TME office building façade in Łódź is covered with thousands of RGB LEDs.

The light emitted by LED structures is released within a junction made of two different semiconductors when, under the current flow impact, electrons switch from a higher to a lower energy state. The energy surplus is converted into electromagnetic radiation. This radiation is always present for any diode type, but for LEDs (Light Emitting Diodes) the materials from which the junction is made are selected so that the energy released generates radiation at frequencies included in the visible spectrum, or, to put it in layman’s terms, so that the junction could glow. This is where two most important features of a semiconductor-based illumination source become apparent: firstly, it requires a DC power supply; secondly, the radiation emitted by a LED structure always falls within a narrow wavelength range, i.e. the human eye perceives it as if a LED emitted only one colour. It can be selected at the production stage by changing or admixing the semiconductors from which the junction is made, however, the principle of operation of the component itself does not make it possible to emit several colours within a single structure.

White LEDs – illusion and alchemy

In order to use LEDs for white light (in fact, colour mix) emission, an additional step must be taken. There are two popular solutions to this problem. The first one is a method applied for several dozen of years on TV, i.e. using three colours (green, red and blue, hence RGB) emitted at a very short distance and subjected to diffusion or observed from a considerable distance to ensure that they “merge” to create the white light illusion. The second technology involves coating a connector with a phosphor-based luminescent substance which, when excited by (usually blue) radiation, emits light within a wide colour spectrum. Using materials with an optimum chemical composition streamlines mass production of those compact components on the basis of which e.g. incandescent lamps or LED strips are designed. Obviously, such factors as the quality (i.e. composition and purity) of the material used and its precise application are of key importance, which in turn is linked to the service life of the entire component. All this requires investing in quality control processes and comprehensive laboratory testing facilities. Therefore, using LEDs that are cheap substitutes for brand-name products most often turns out to be the opposite of saving. At this point, it is high time we ended our theoretical considerations and moved on to the technologies implemented to improve LEDs, making them a source of light that is perfectly suited to human needs and biology.

MANUFACTURER’S SOLUTIONS

Issues related to colour rendering, illumination and its impact on people are the subject of much debate and research, in which the lighting manufacturers’ opinions and input are extremely valuable. To the consumers’ satisfaction, the suppliers strive to offer increasingly affordable and efficient solutions, presenting innovative technologies to improve energy-efficient light sources. Suppliers of optoelectronic components are at the vanguard here, as it is their products that are used in the design of lamps, light bulbs, fluorescent tubes, strips and other items that then hit shop shelves. As we have mentioned above, we will present an overview of the product range and technologies offered by one of the leading global LED suppliers, Bridgelux.

Thrive™ technology

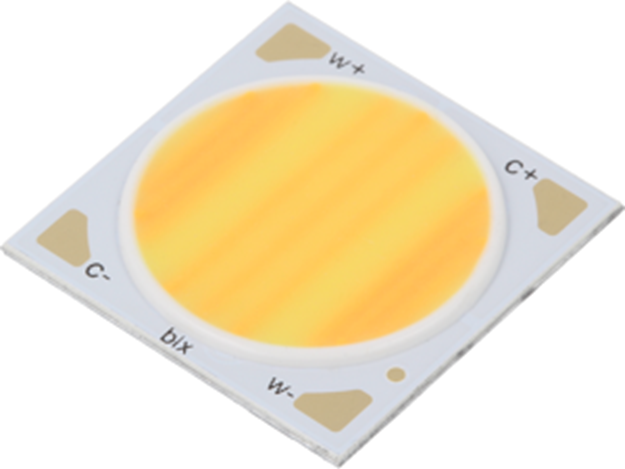

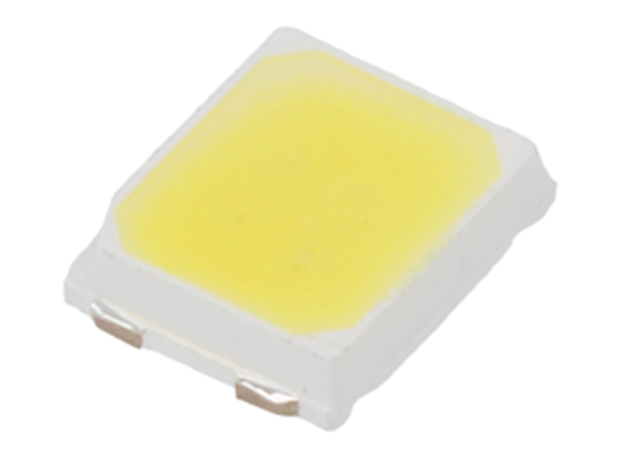

Bridgelux Thrive™ is a product series including SMD LEDs and LED COBs (Chip-On-Board – a miniaturisation method in which semiconductor structures are connected directly with the printed circuit). In the former case, the housing accommodates a single LED structure, whereas in the latter case, structures are densely packed on a shared ceramic or metallic base, and subsequently covered with a luminescent material layer. Such products are based on the ASD (Average Spectral Difference) technology elaborated by Bridgelux and consisting in measuring the averaged, spectral departure from the natural light. Thus, blue phosphor is used to create such LEDs (as opposed to Bridgelux competitors using violet phosphor), which increases the cyan shade intensity in the emitted light, bringing the illumination closer to the solar spectrum, and at the same time increasing the component service life. This has enabled the manufacturer to achieve superior colour rendering index values (95 or 98 as per CRI, over 90 as per TM-90), which translates into great users’ comfort and the possibility to use components for professional applications, such as TV studio illumination. The Thrive™ line products are available as diodes and power diodes (0.2– 2.4 W) with the efficiency reaching 144 lm/W. They are housed in standard 2835 packages and modules with a 13.5 x 13.5 mm footprint (height – 1.7 mm), and also boast a wide fluorescence angle, typically 120°. They come in versions with a varied colour temperature, i.e. from 2700 K to 6500 K, and this parameter is adjustable in selected models.

The street light hue can significantly impact drivers’ concentration levels.

Tunable-White – human-centred designs

The brightness of a single LED may amount even up to 3980 lm.

The above-mentioned light temperature setting is related to the increasingly more popular issue of the Human Centric Lighting (HCL), which has become a hype especially among architects and interior designers. It emphasises the need to adjust artificial interior illumination to human needs. This is achieved, for example, by recreating, through illumination, the natural light cycle, i.e. changing the colour temperature according to the time of day (warmer hues in the morning and evening). Some related techniques can be implemented to stimulate concentration or, conversely, relaxation. All in all, this is how optimum illumination is obtained in household, school, hospital, or office conditions. In such applications, products from the Bridgelux Vesta ® series may come in handy, as they offer you the option to adjust the colour temperature (thanks to the Tunable-White technology). It can be set within various ranges: from 1800–3000 K to 2700–6500 K. The rated power of such components ranges from 8.7 W to 31.8 W (brightness from 3980 lm). Regardless of the model and the CCT value selected, the light emitted by the components achieves a CRI value of at least 90, which is satisfactory even for professional applications.

Dim-to-Warm LEDs

One disadvantage of LED light sources is their unusual behaviour when dimmed by current flow limitation (and this technique is most often used in dedicated power supply modules). As the intensity decreases, the light colour becomes “cooler”. For most users, this phenomenon is unintuitive and often counter-productive, because dimming a lamp should result in warmer illumination, as is the case with classic incandescent or halogen light sources. As part of the Vesta® series, Bridgelux offers LEDs that imitate the behaviour of traditional light sources, i.e. Dim-to-Warm products. When operating at full power (even up to 109.3 W), they generate light with the temperature of 3000 K, and, as the intensity decreases, the temperature is lowered accordingly, down to 1800 K.

F90™ technology

While analysing the parameters of optoelectronic solutions available on the market, it can be observed that higher CRI values are typically associated with lower efficiency. This is due to the properties of the materials coating the LED structures, i.e. those used to convert the homogeneous radiation emitted from a semiconductor structure into a broad light spectrum. Traditionally, red nitride-based luminescent material is used in such solutions. However, the F90™ series products by Bridgelux use a different substance, i.e. a narrow-band red, PFS-based (potassium fluorosilicate) luminescent material. It ensures a higher colour rendering index (CRI at 90) at a power rating which, in competitive solutions, makes it possible to obtain a CRI value equal to approximately 80. This effectiveness translates into efficiency reaching even 204 lm/W. The application of PFS also increases the emitted light intensity in the red colour band, which is desirable in shop or display illumination applications. Therefore, Bridgelux recommends the F90™ products mostly as components used to manufacture illumination sources intended for clothing stores or shopping centres, e.g. line lamps high-bay lamps, spotlights etc. The F90™ products are enclosed in the standard 2835 package and boast a power rating of 0.2 W).

F90™ components are housed in typical 2835 packages.

Note also that the TME product catalogue includes a rich assortment of complementary products to help you make the full use of LED light sources and the products presented here. This includes power supply modules, heat sinks, and aluminium profiles for LED strips.